- Accueil

- >

- Composites

- >

- Produits

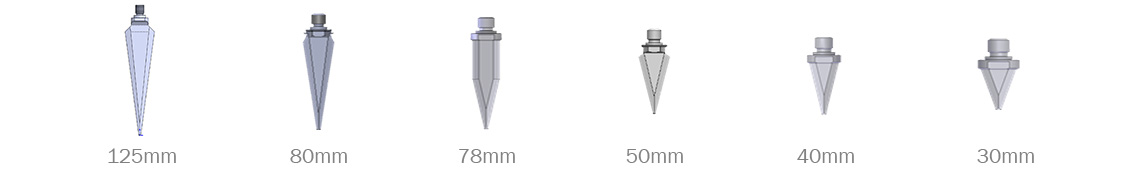

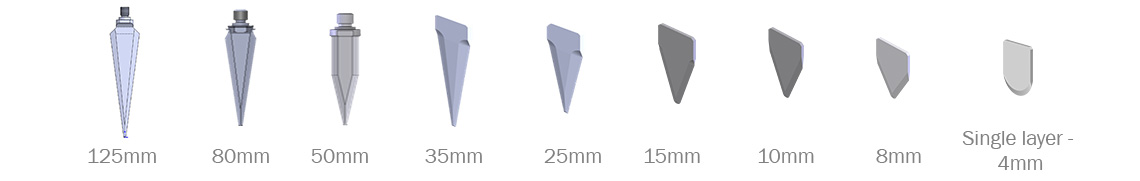

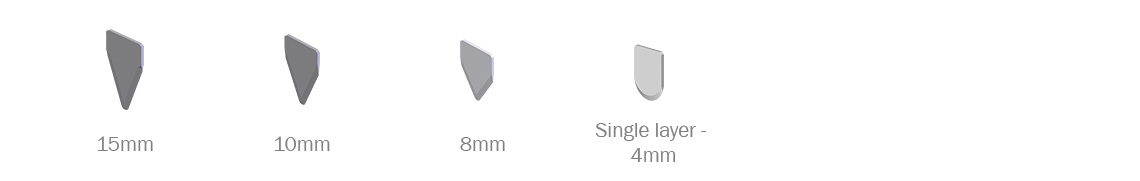

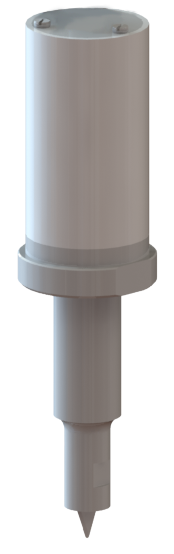

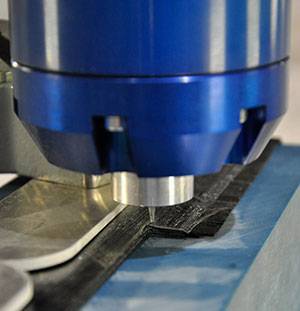

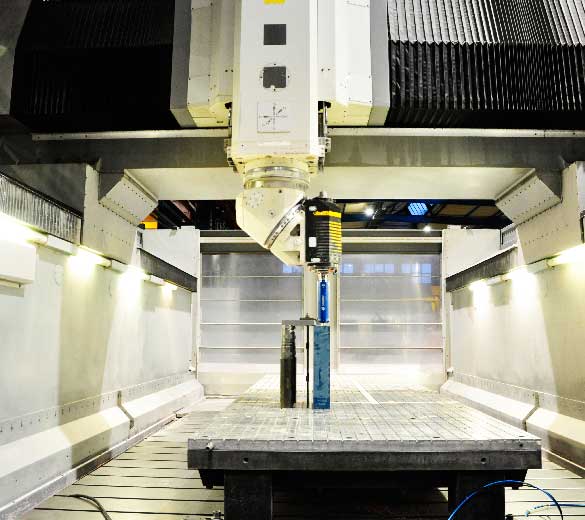

SONIBLADE – Effecteurs embarquables de découpe ultrasons

- Société

- Composites

- Textile

- Agroalimentaire

- Packaging

- Plasturgie

- Plasturgie

- Centre Technique

- Centre Technique

- Centre d’essais et pré-séries

- Formation

- Ingénierie et avant-projet

- Ligne de production automatisée

- Produits

- Technologies

- Métal

- Métal

- Produit

- Technologie

- Technologie

- Soudure des métaux par ultrasons

- Actu

- Téléchargements

- Contact

- Société

- Composites

- Textile

- Agroalimentaire

- Packaging

- Plasturgie

- Métal

- Actu

- Téléchargements

- Contact