- Accueil

- >

- Plasturgie

- >

- Technologies

Soudure ultrason plastique

Soudure ultrason plastique – Principe de fonctionnement

La soudure ultrason trouve ses applications dans de nombreux domaines parmi lesquels l’industrie des thermoplastiques. Alors, comment fonctionne-t-elle ?

Les ultrasons sont des vibrations mécaniques semblables à celles produites par n’importe quel instrument de musique. Ces vibrations sont appelées des ultrasons parce qu’elles sont à une fréquence supérieure aux capacités auditives de l’oreille humaine (supérieur à 16 kHz).

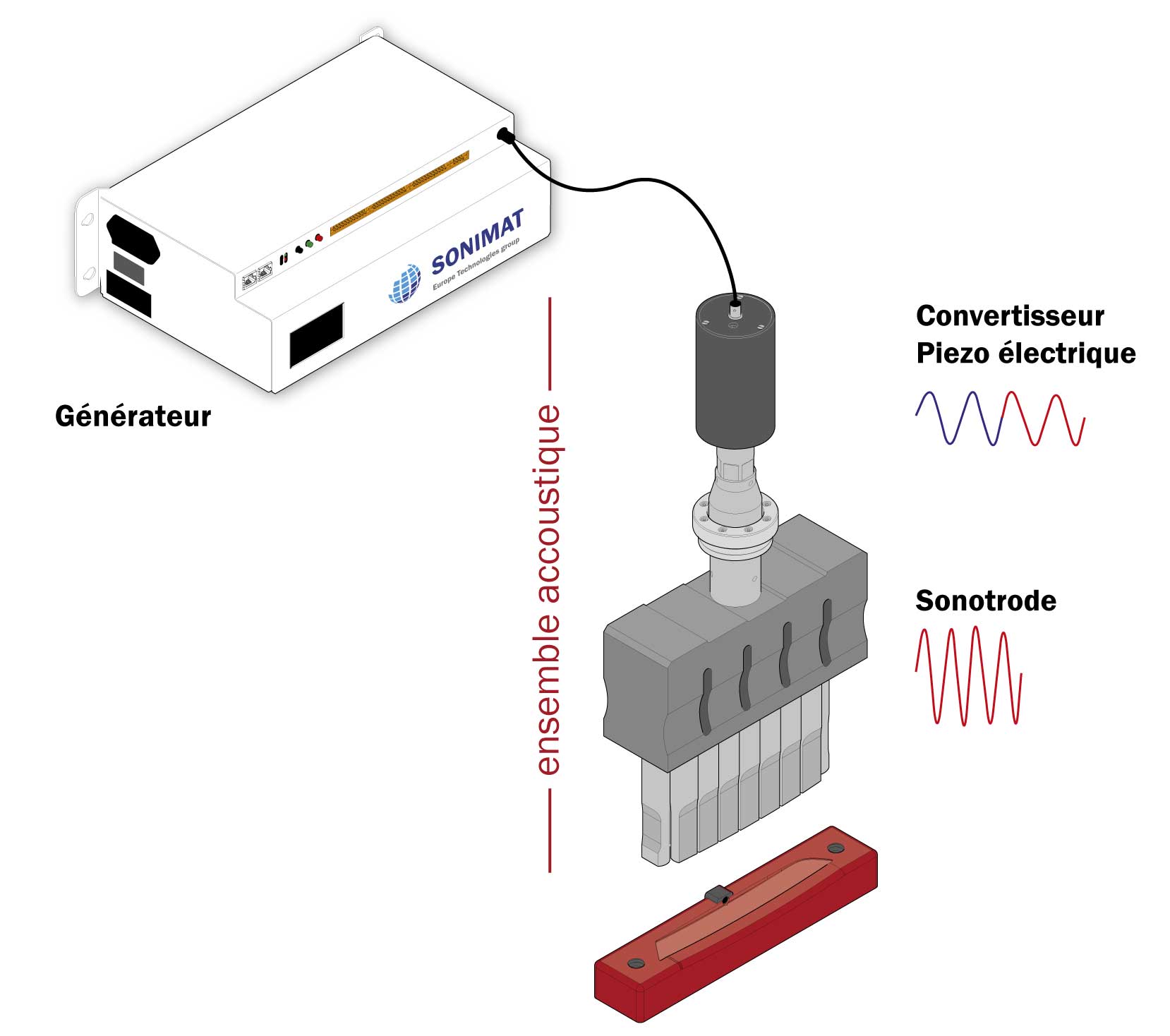

1. Dans un ensemble acoustique, ces ondes de pression sont produites par un générateur. Celui-ci envoi un courant alterné de la même fréquence que le convertisseur (ou transducteur).

2. Ensuite, le convertisseur, qui est composé de céramiques piezo-électriques, les transforme en vibrations mécaniques.

3. Les vibrations mécaniques vont alors générer une chaleur de frottement dans le plastique et exciter ses molécules, qui vont à leur tour, se mettre en mouvement. Le plastique s’assouplit et fonds permettant aux composants de se lier. L’action de soudage est réalisée par la sonotrode.

La technologie de soudage ultrason plastique est très adaptée au bouterollage plastique.